9-Tech: Italian startup recycles solar panels sustainably

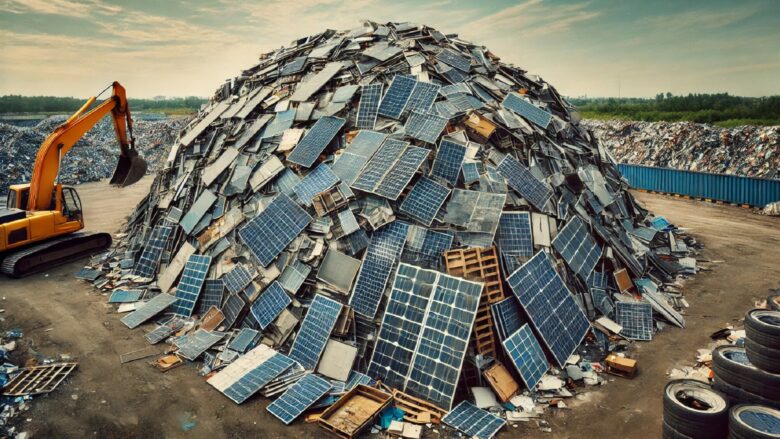

The Italian startup 9-Tech has set itself the goal of making the recycling of solar panels more sustainable. This is absolutely necessary because according to t3n, it will be necessary to recycle tens of millions of tons of solar modules in the coming decades. Even though solar modules generate clean electricity, their production and recycling are currently not very environmentally friendly. According to current calculations, between 54 and 160 million tons of solar modules worldwide will reach the end of their life by 2050 and will then have to be recycled.

E-waste: A record 62 million tons of electronic waste worldwide in 2022

Environmentally friendly solar panel recycling is a major challenge

So far, the recycling of solar panels and corresponding modules has focused mainly on glass, aluminum, and other easy-to-process materials. According to experts, over 85 percent of the materials that photovoltaic modules are made of can currently be recycled without any problems. The silicon, silver, and copper that they also contain are significantly more valuable, but also much harder to reach. As a result, it usually ends up in the trash – which is not very environmentally friendly. One way to tackle the problem in the future is to develop panels that do not use expensive silver contacts, for example.

In contrast, environmentally friendly production of the panels is much more difficult. And even the best recycling methods can currently only recover around 90 percent of the materials used in solar modules – often using toxic chemicals. Only a few of these are used on a large scale. The Italian start-up 9-Tech has therefore developed its own approach to recycling solar panels and modules in an environmentally friendly way. With its technology, which the young company has been testing for two years, it should also be possible to reuse 90 percent of the materials. This should work without the use of toxic chemicals.

Study: Up to 11 million tons of plastic waste on the sea bottom

9-Tech builds larger recycling factory

9-Tech relies on a 400-degree incinerator, an ultrasonic bath, and mechanical sorting. The Venice-based startup carries out the tests in a converted freight container. The process is more expensive than existing recycling methods. The hope is that the resulting materials – silicon, silver, and copper – can offset the additional costs. According to 9-Tech, around 500 grams of silver can be extracted from one ton of solar modules.

Now the 9-Tech method must first pass the next endurance test. Then it will become clear whether the startup can operate profitably. In the next 18 months, a larger recycling factory is to be built that will be able to process up to 800 modules per day.

9-Tech is not the only company working on effective and environmentally friendly methods for recycling solar panels. Most of the time, it involves grinding the silicon, metal, and polymer layers into small pieces and recovering the silicon and metal using thermal or chemical processes. Other methods rely on laser irradiation, high-voltage pulses, optical sorting, chemical solvents or etching and removing layers with a hot knife.