Lam’on: On a Mission to Make the Printing Industry More Eco-Friendly

“Every year over 4M kilograms of plastic is used for laminating. And in most of the cases, when paper and plastics are mixed, they are not recycled. This is a huge invisible problem”, Gergana Stancheva says. The reason for this is that paper, once laminated, is hardly or not at all recyclable – it turns into mixed media and goes straight to the incinerators or in landfills This applies to many products from magazines, to posters, paper cups and smartphone packages.

In 2017, the photographer Angela Ivanova and the illustrator Gergana Stancheva joined a project that aimed to create a completely biodegradable children book. They started looking for recyclable alternatives to make it glossy (usually done by laminating) and ended up purchasing degradable laminating film from Taiwan.

As the material arrived, it turned out it was indeed the right type of film, however, there was no way to stick it to the paper. There was no glue layer, and with the conventional one, it would mean that it again couldn’t be recycled. Ivanova and Stancheva then decided to step out of the project and dedicate themselves to the development of a solution for this printing industry issue. Thus Lam’on was born.

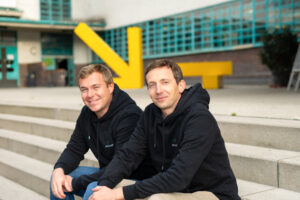

The two Artists and the Academy of Science

Equipped with this idea Stancheva and Ivanova went through the idea stage acceleration program for green businesses ClimateLaunchpad to learn how to turn this product into business and find the right partners and clients. They also received their first funding of €15K to develop the idea.

Knowing they would need a partner with a scientific background to help them develop the materials, co-founders made a list of organic chemistry specialists from the Bulgarian Academy of Science (BAS) and started sending out emails. Philip Ublekov, a researcher at the Institute of Polymers of BAS, responded and soon became the third partner in the venture.

To create the desired material and glue, the newly formed team of three ran various experiments. Lam’on finally concluded to base the laminating film on polylactic acid, which is basically made out of cornstarch and other ferments. Ublekov also developed a formula for a water-soluble glue that would make the separation of paper and laminating film easy, which according to Ivanova is the more significant innovation of Lam’on.

Unconventional material, conventional production

In 2018, the biodegradable laminating film of Lam’on was already out of the lab and the team is running test phases together with another Bulgarian partner. “The great thing about this product is that it could be produced in normal production sites where the conventional laminating film is made too”, Stancheva explained. Being well connected in the printing industry in Bulgaria, helped Ivanova and Stancheva to quickly find partners and start testing the application of the film.

“We have started pilot test with several print houses in Bulgaria and for now this is our target market. I don’t know whether people are familiar with this, but a lot of the printing materials in UK, Germany and Spain are actually printed in Bulgaria”, Stancheva explained.

Meanwhile the two co-founders are often travelling to Germany to present the product to other print houses there as well. “The product is well received almost everywhere we present it. Not least, because it has the same features as the conventional laminating film, comes at the same price but is much more eco and health friendly”, Ivanova added. According to her, Lam’on is a solution also to another important issue of the printing industry – the toxicity of glues in the conventional production.

The Challenge

The less than two years old Lam’on has recently made it to the national finals of the global social entrepreneurship contest Chivas The Venture. This means that alongside with the pilots, the next months for Ivanova and Stancheva will try to gain more popularity and funding for the company. “We want to eventually close our production cycle. This would require $230K to set up our own production site – rent the space and buy machinery, and also build up the team”, co-founders explained. The first phase of the contest is an online voting in April, which will decide which teams will go to the global finals in May.

No matter the results of the contest, the team is determined to make Lam’on work. Ivanova and Stancheva have also applied for the next acceleration program of the European Climate-KIC. “We want to perfect this product for the printing industry first, and then eventually move to other industries as well”, Stancheva explained.

Biodegradable materials that could replace plastics are a hot topic recently, especially in packaging ever since the Single Use Directive of the EU was issued. The product of Lam’on could also be used in the packaging sector, which has been experiencing a shift towards more eco-friendly materials recently.